The making of the Adventure Time festival furniture

Overview Process

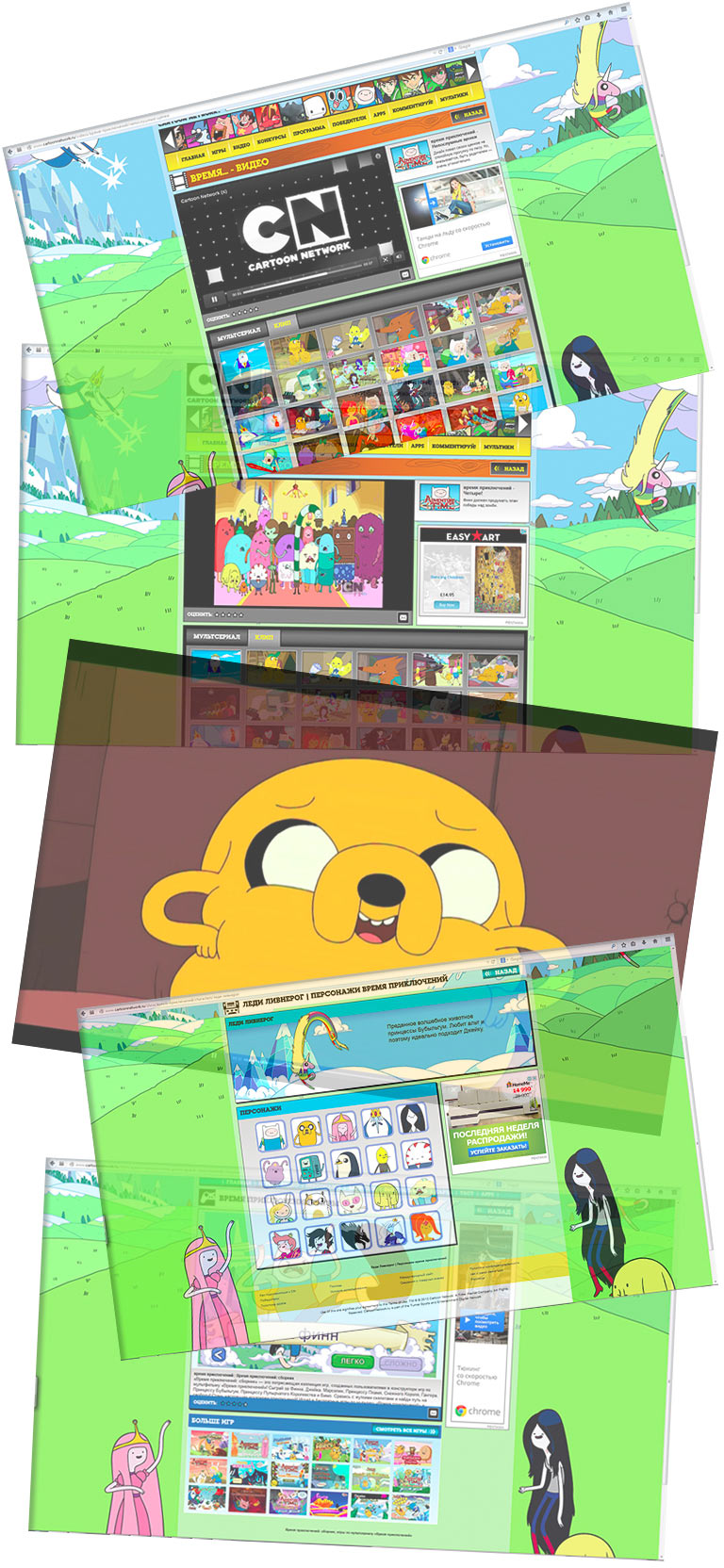

Everyone in the team has watched Adventure Time. Watching the series again, visiting fan websites.

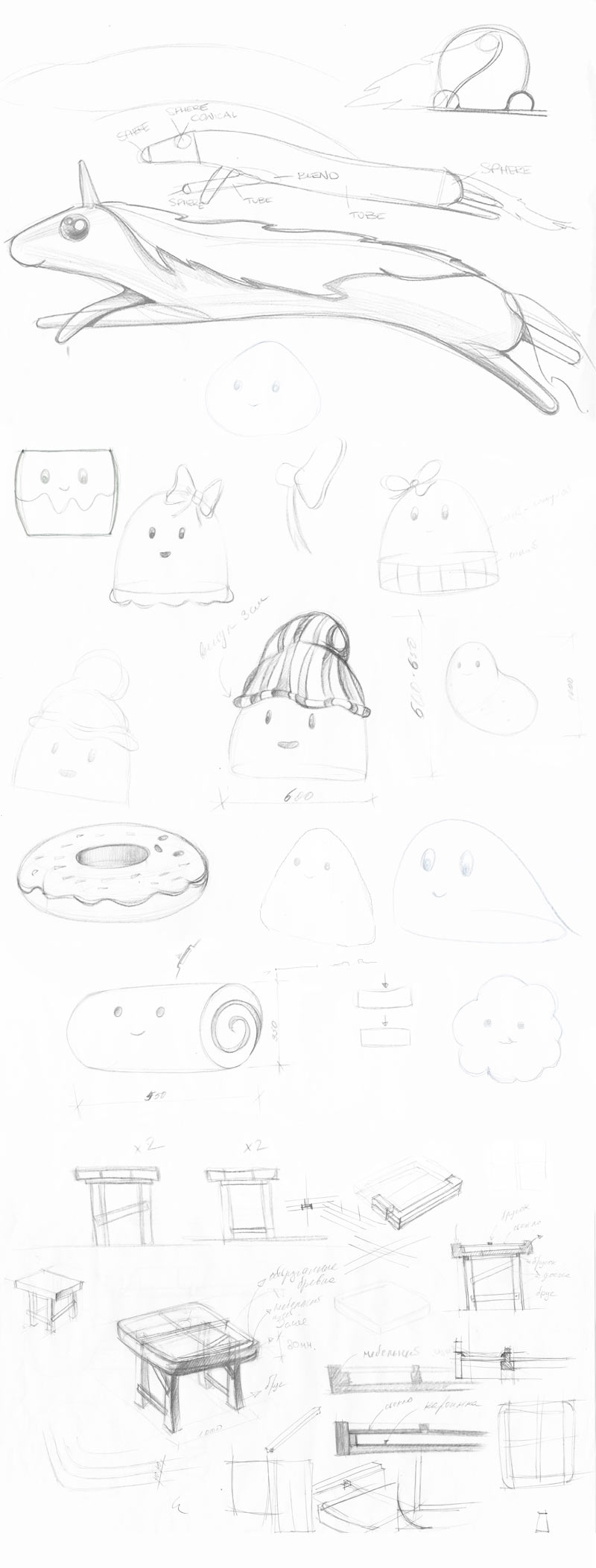

Yegor draws the first drafts to give us a start.

Trying out the models, suggesting different variants.

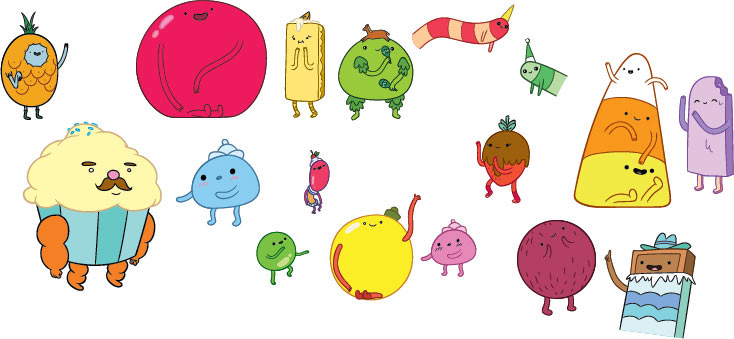

The client chooses the cubes with letters, the unicorn bench, poufs with funny faces and the bench that in the course of the meeting transforms into a table with stools. Besides, the client asks to make sure each pouf represents one of the Candy People.

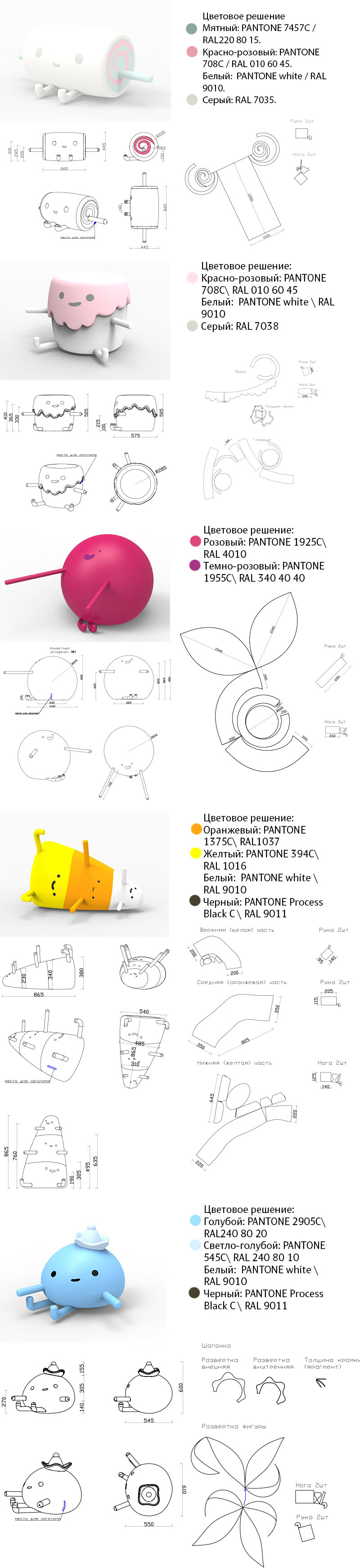

Together with the art director choosing five of the Candy People.

Drawing detailed sketches.

Simultaneously developing all of the objects. Creating models based on the sketches, making dimensional drawings, choosing materials and colors.

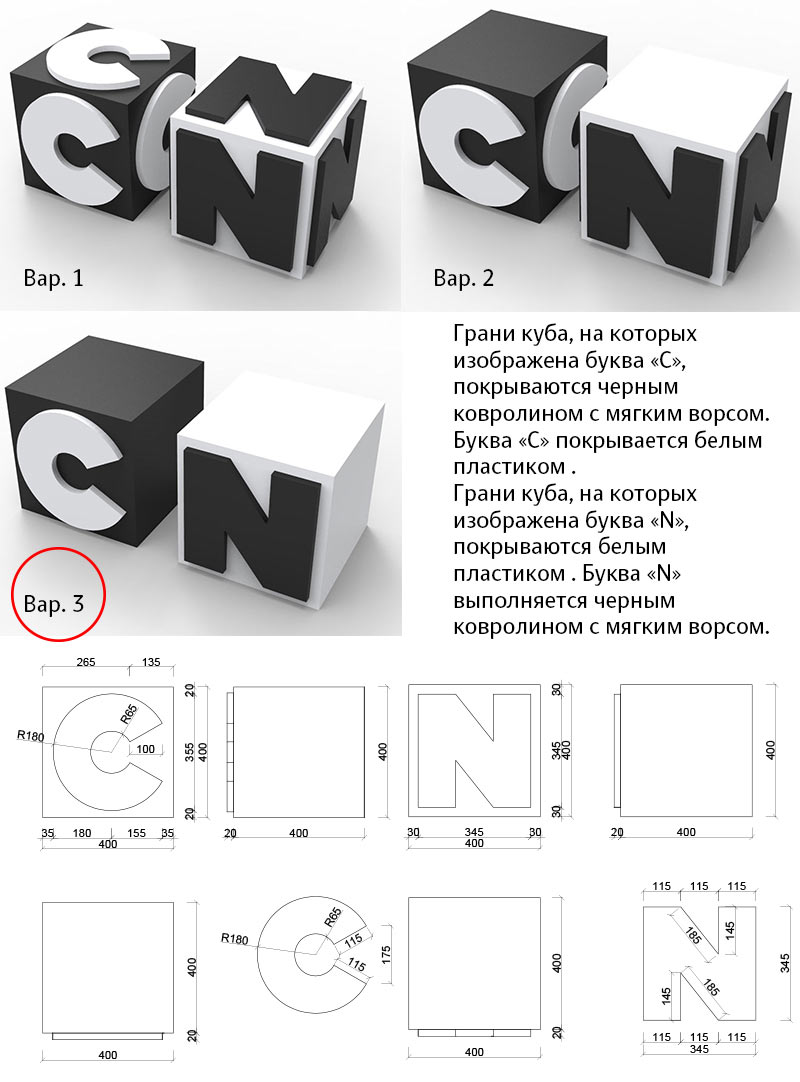

Cubes with the Cartoon Network logo.

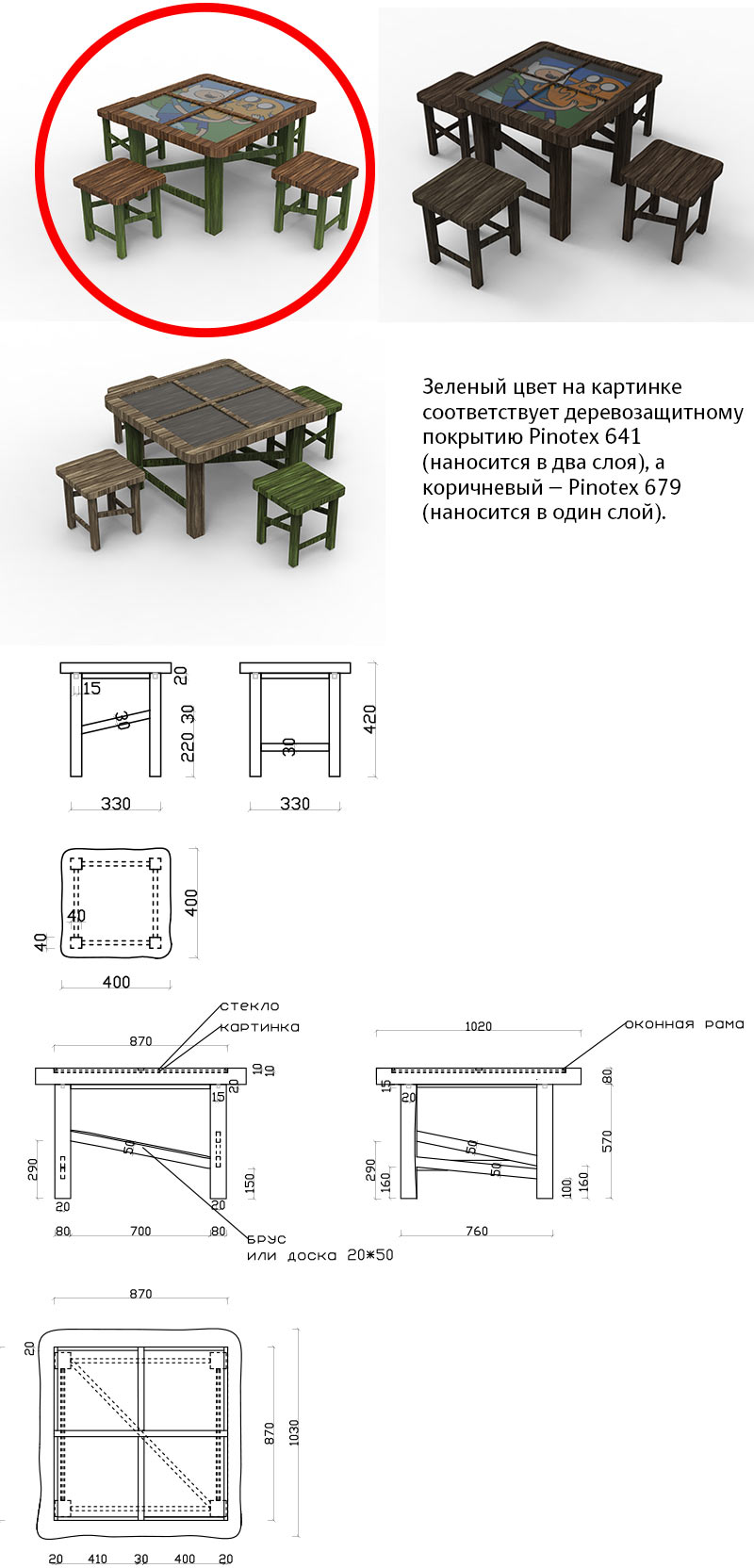

The table and stools.

The Candy People. To make it more clear, creating a development drawing of the poufs.

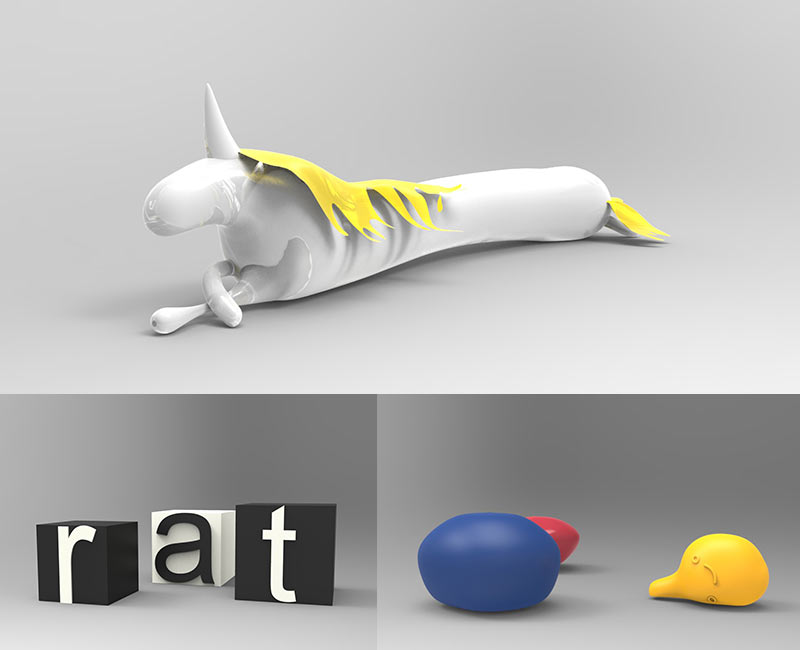

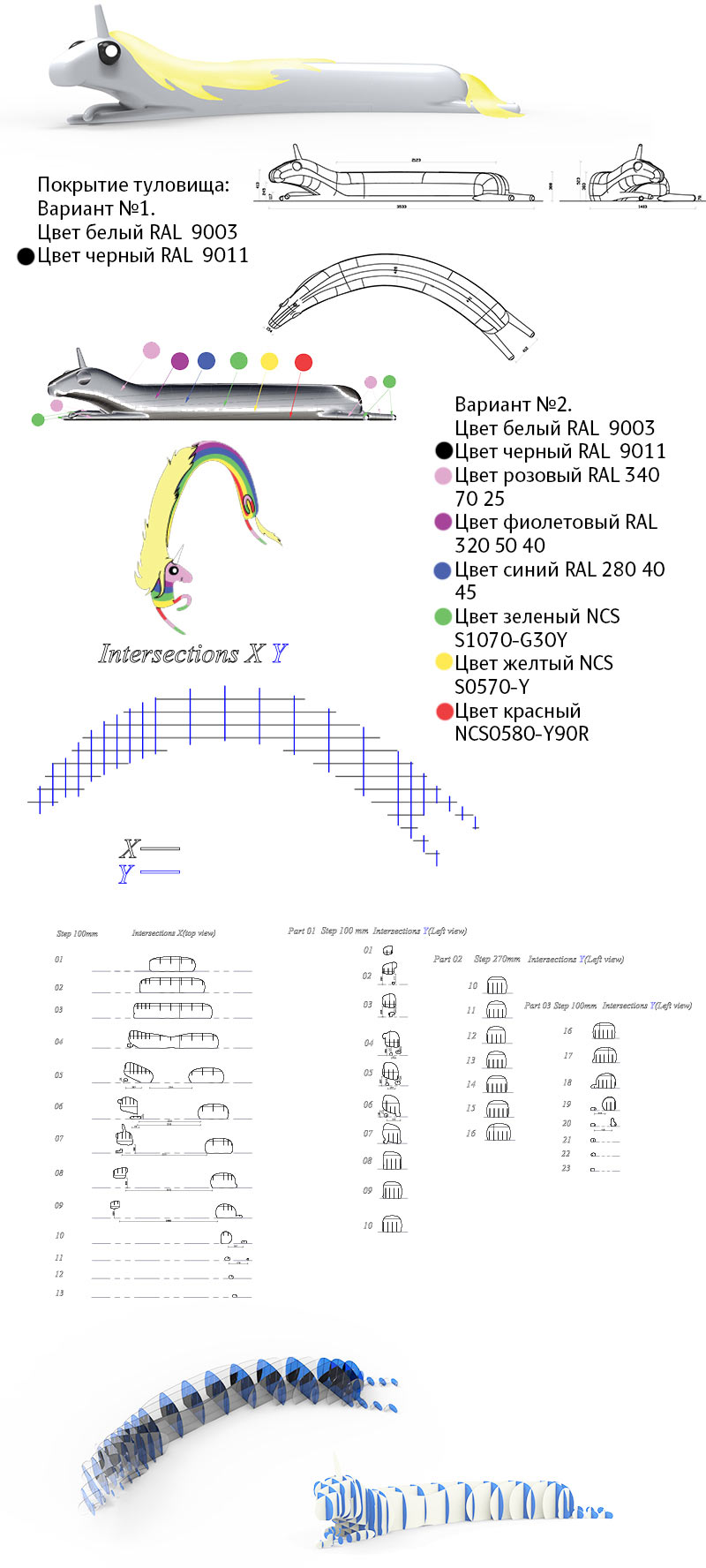

Lady Rainicorn. Building cross-sections that would ensure the figure retains its smoothness during production. Learning that literally yesterday our production partner purchased a seven-axis mill which means there will be no problems with smooth carving.

Additionally creating a 3D-printed model of Lady Rainicorn to better show the shape of the mane and tail.

Choosing the material for each object, examining how the laser-engraved logo looks and how colored oil works on wood.

Meanwhile the client sends backgrounds for the picture that will be placed under the glass tabletop and tells us we have to design two tables instead of one.

Looking for a nice shot.

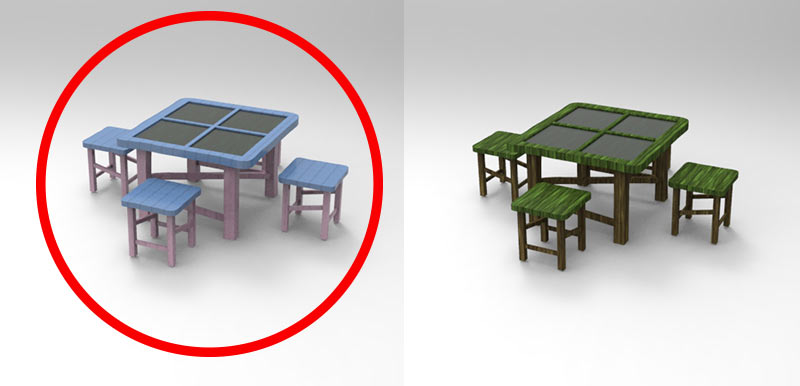

Realizing that the main characters in the pictures will be Finn and Jake together with Fionna and Cake. This gives us the idea to create another table with inverted colors. Choosing to go with colored oil for finish again to make sure the textures of the tables look similar.

Sending logos for each of the tables along with guidelines on where they should be printed or affixed.

There are six variants in total. The logo will be laser-engraved on the tables. The rest of the logos have two color solutions and various placement.

Getting a photo report from the manufacturer and visiting the factory to provide designer supervision.