The making of the Pepelkus cigarette receptacle

It all started with Iliya Varlamov’s post on city projects: “The projects we realize on our own: city cigarette disposal. Within this project we are going to finance the manufacturing of or purchase outdoor cigarette receptacles and install them along Tverskaya street in Moscow. This would be an example of how it doesn’t take much to improve your street.”

From this point on the project really took off.

Project technical specifications:

- —

- should attach to building walls and primarily on street poles;

- —

- should be easy to empty for street janitors;

- —

- should be mostly enclosed, to deprive lit cigarettes of oxygen and inhibit burning as well as for preventing cigarette boxes and other trash from entering the container;

- —

- the manufacturing method should be the most economical, omitting foundry and stamping processes.

Visiting Tverskaya street for the reality check: Holy smoke!

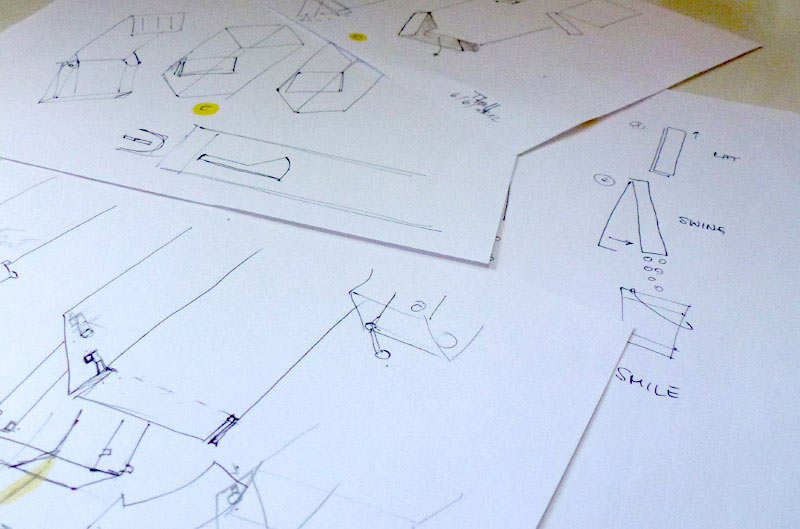

Searching for ideas.

Diving into the process.

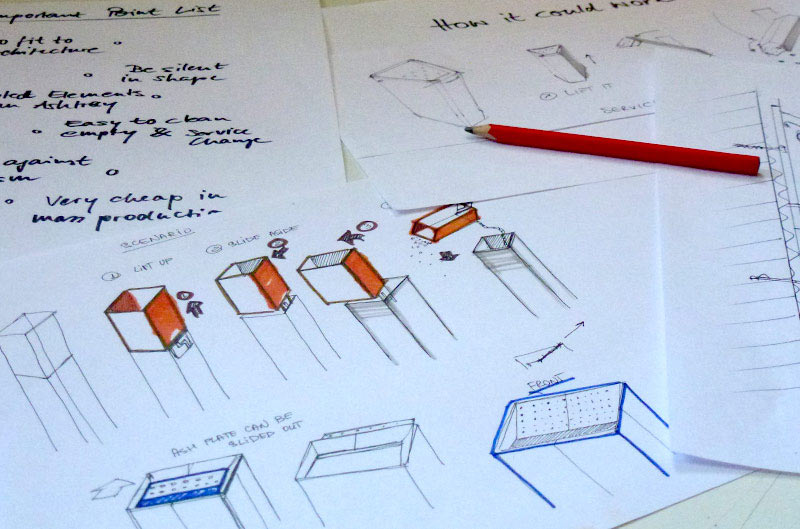

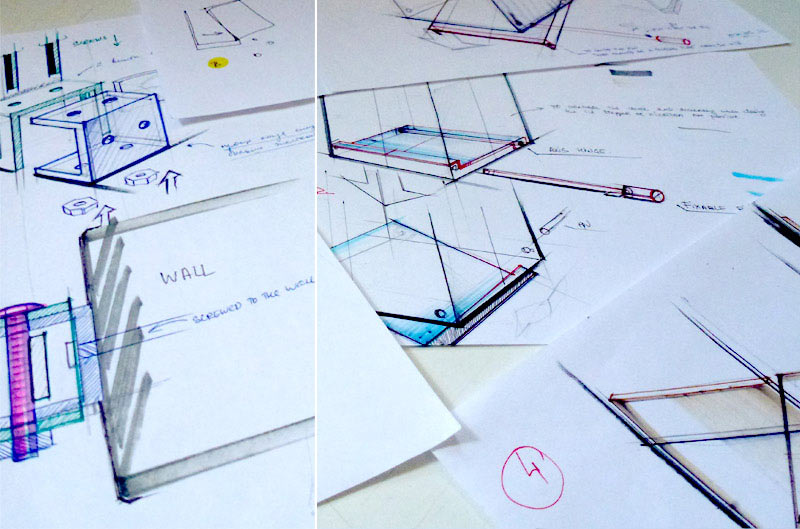

Determining the optimal size and structure.

Defining the details.

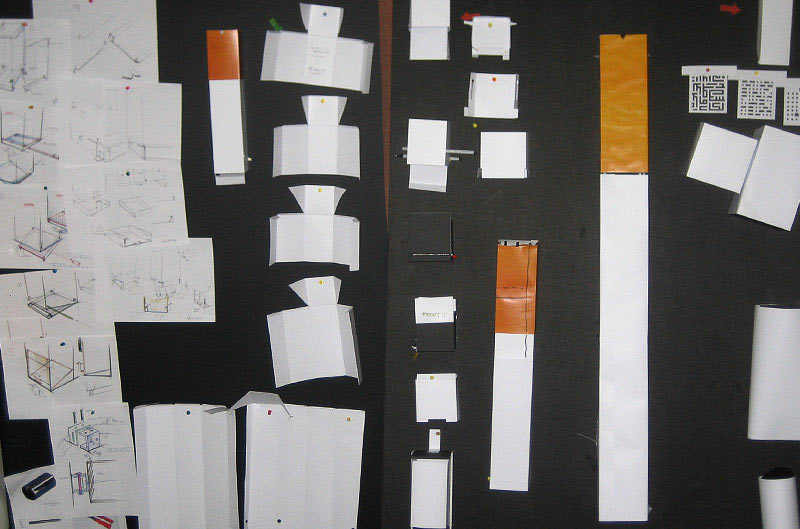

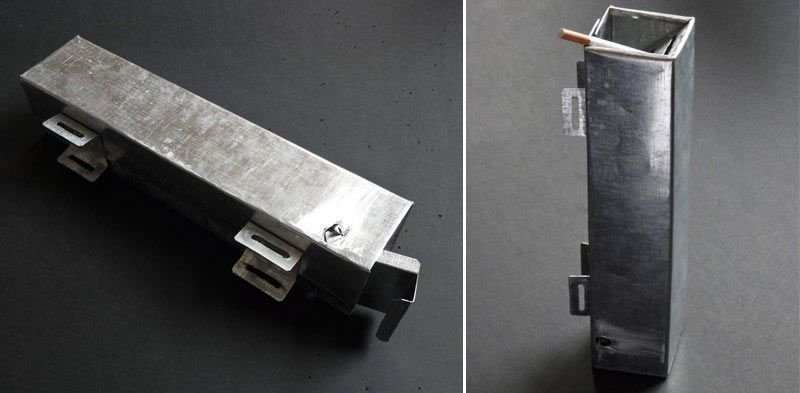

Finalizing our choice and moving on to metal models.

Field-testing our mock-up.

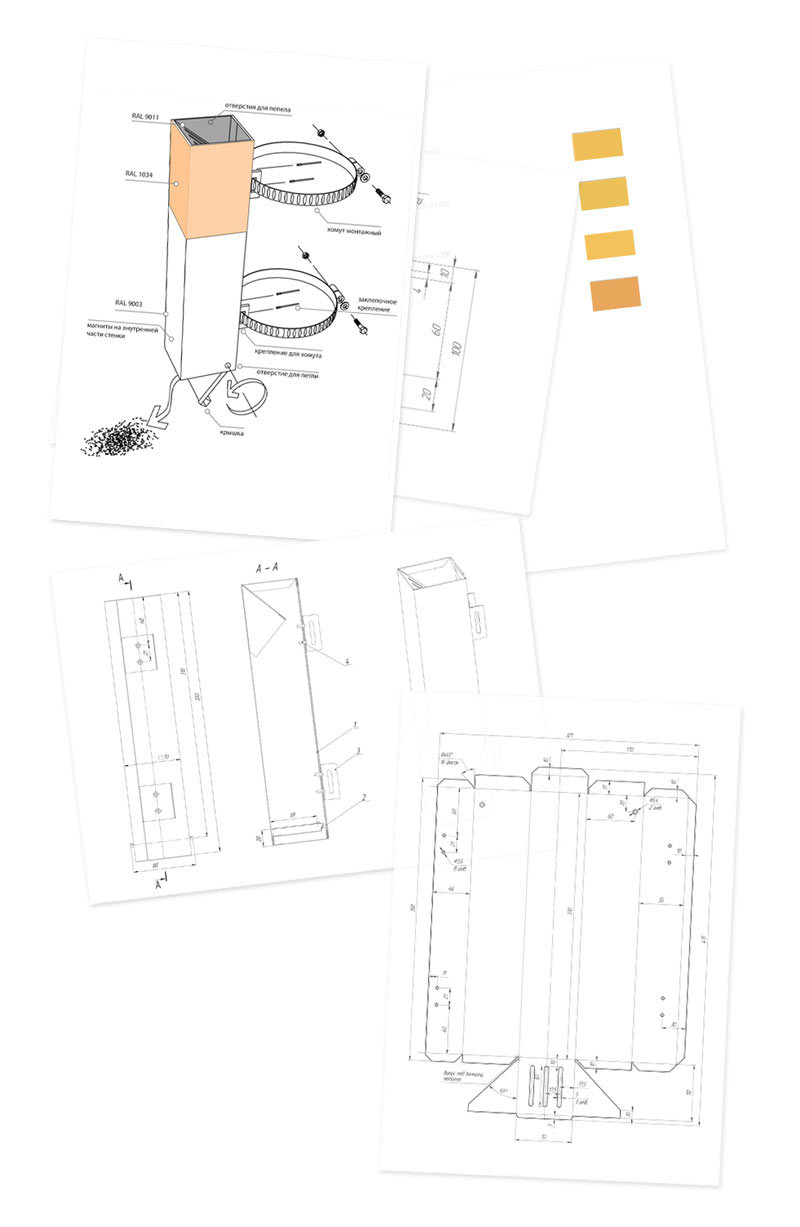

Preparing the drawings and schematics.

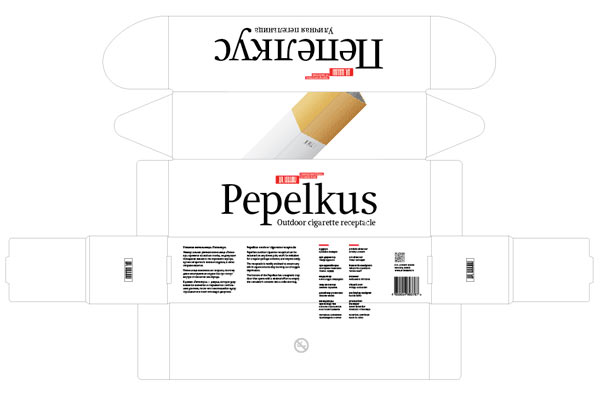

Using the Pepelkus blueprints to determine the actual packaging dimensions.

Dialing in the dimensions and constructing the box.

Typesetting the packaging layout.

Ending up ditching the horizontal text placement. The final packaging houses Pepelkus cigarette receptacle and two plastic screw clamps.