The making of the Atmarkus 3G mug

An idea to render Atmarkus in frosted glass pops up.

The initial prototypes turn out excessivly heavy and the frosting on the cake simply does not work.

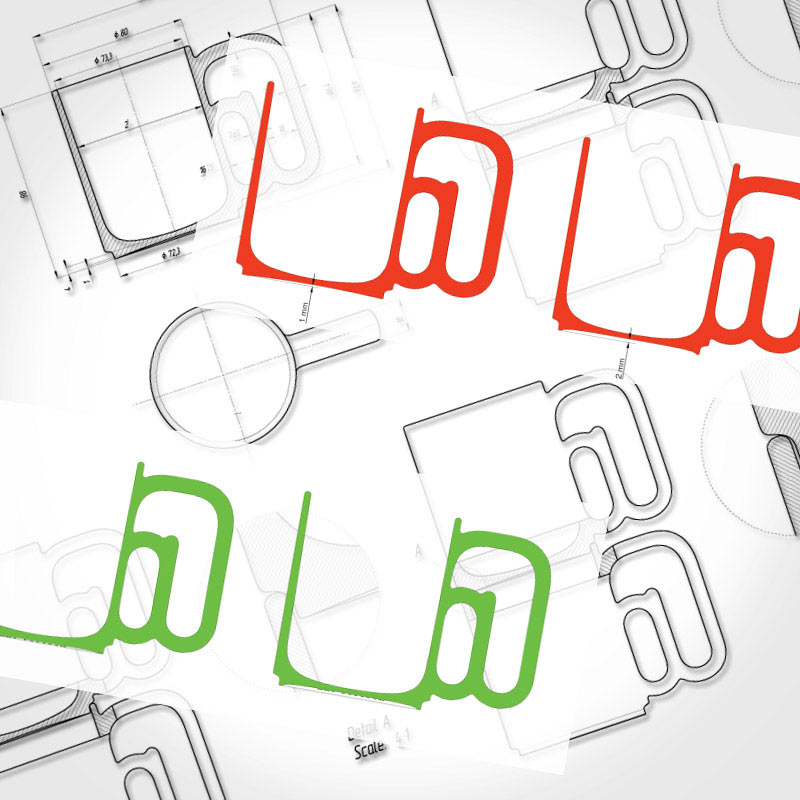

Fine-tunning the mug’s shape and sending it through a weight-loss program. Preparing styrofoam and ABS plastic models.

Working on the outline. Defining the walls and handle thicknesses.

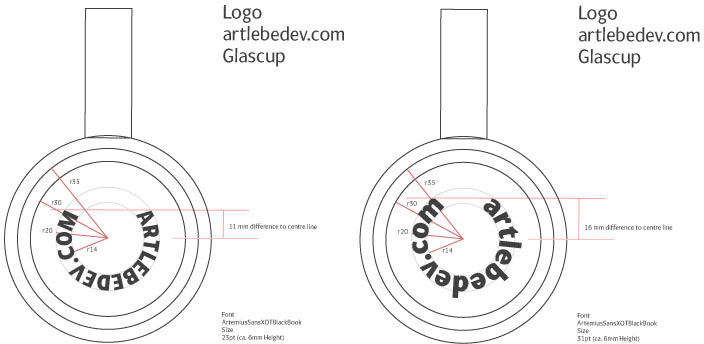

Sizing and positioning the text on the bottom.

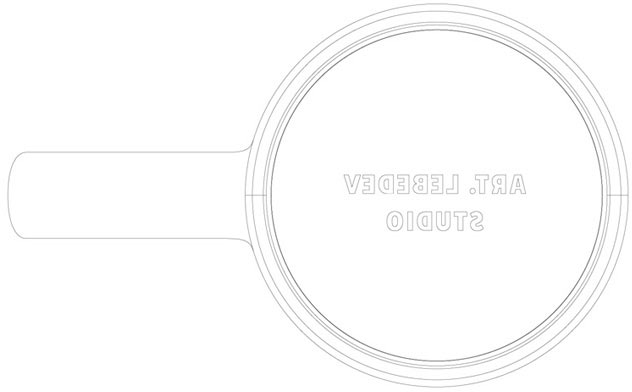

Testing a different approach with the text seen from the inside.

Analyzing a prototype.

Comparing the older and more recent prototypes side by side before sending the new series to production.

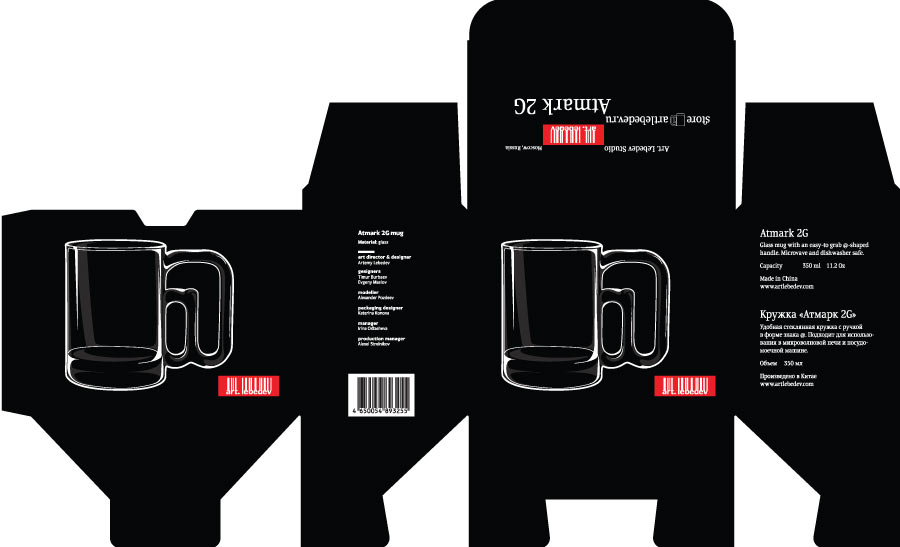

Digging up the basic layout for Atmarkus packaging.

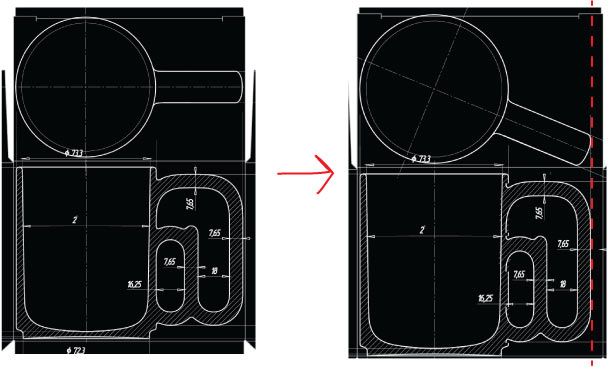

Changing the dimensions according to the new layout.

Updating Atmarkus model and fixing the layout bug.

Pushing the logo behind the mug.

Updating the title, improving the construction, adding a QR code, and running the final touch-ups.